Easy Application of Ceramic Spray Coating: DIY Guide for Automobile Fanatics

Easy Application of Ceramic Spray Coating: DIY Guide for Automobile Fanatics

Blog Article

Achieving Expert Results With Ceramic Spray Coating: Proven Methods and Ideal Practices Exposed

As experts in the field of auto detailing and surface security are constantly seeking means to raise the top quality of their job, the application of ceramic spray coverings has emerged as a game-changer. By uncovering the proven techniques and ideal practices behind ceramic spray finishing, a world of possibilities opens up for those looking to elevate their craft and deliver remarkable coatings.

Benefits of Ceramic Spray Coating

The advantages of using ceramic spray covering in various applications are well-documented and commonly acknowledged in the industrial and automobile markets. Ceramic spray finishings use phenomenal security against ecological contaminants, UV rays, chemicals, and oxidation, offering a durable shield for surfaces. One of the main advantages of ceramic spray coating is its superior longevity contrasted to traditional waxes or sealants. This longevity equates to set you back financial savings for customers and services alike, as the need for regular reapplications is significantly reduced.

In addition, ceramic spray coatings develop a hydrophobic surface area that wards off water and protects against water spots, making cleansing and maintenance easier and less time-consuming. The boosted gloss and deepness of color offered by ceramic finishes can give lorries and commercial devices a display room coating that lasts. Additionally, the scratch-resistant buildings of ceramic finishes help maintain the visual allure of surfaces with time, contributing to the general worth and longevity of the covered items. To conclude, the benefits of ceramic spray finish make it a favored option for shielding and boosting surface areas in a range of applications.

Crucial Tools and Materials

Having recognized the advantages of ceramic spray layer, it is necessary to lay out the crucial tools and materials needed for its efficient application in numerous sectors. To accomplish specialist outcomes, the following materials and tools are essential:

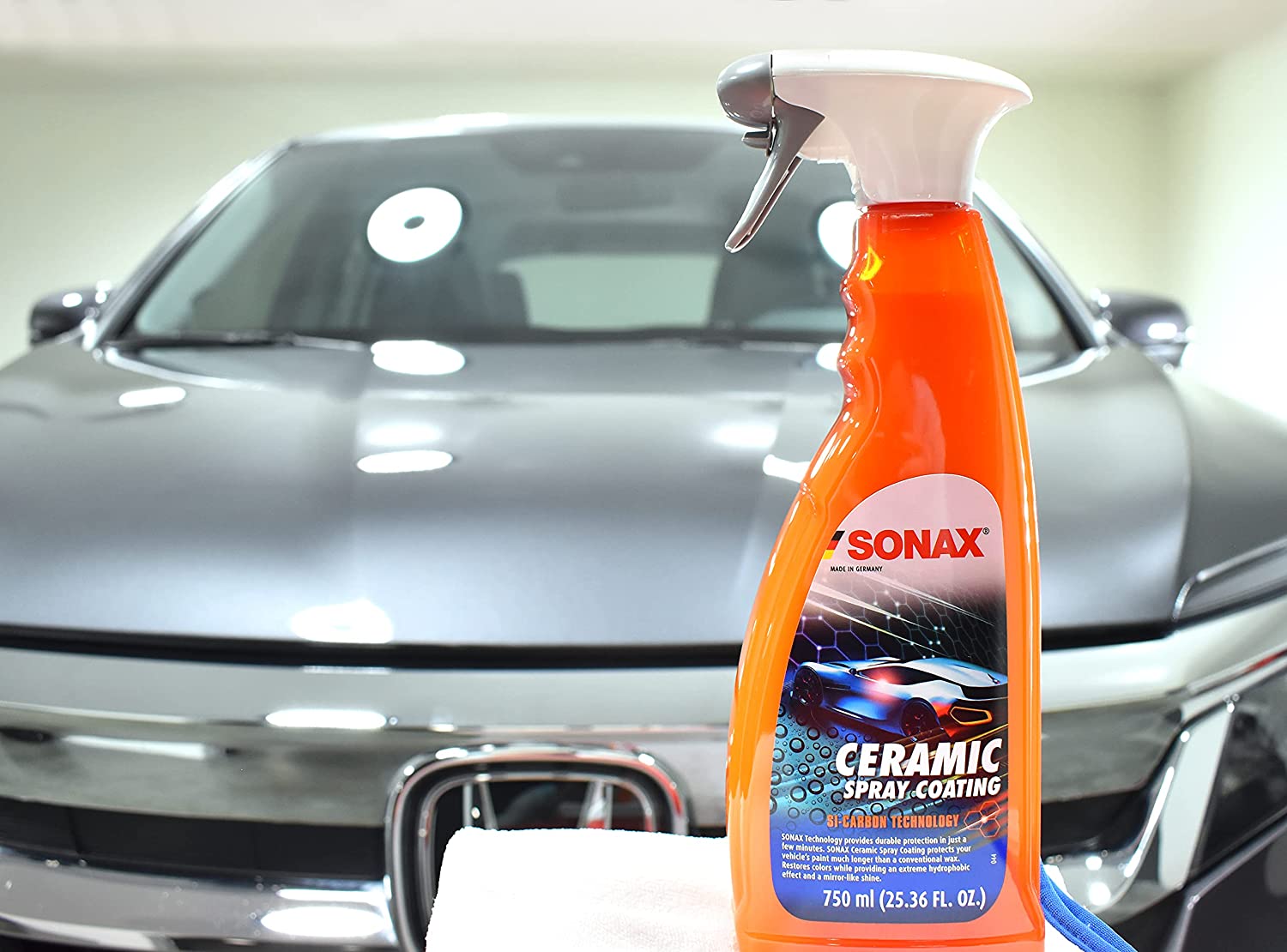

Ceramic Spray Layer: The heart of the procedure, the ceramic spray finish itself offers the safety layer that enhances resilience and visual appeals. - ceramic spray coating

Microfiber Towels: Made use of for cleaning down the surface prior to using the ceramic spray covering and for buffing off excess product after application.

Spray Bottles: Important for uniformly dispersing the ceramic coating onto the surface.

Protective Equipment: Handwear covers and masks to make certain safety during the application procedure.

Polishing Compound: For preparing the surface by getting rid of any kind of blemishes before applying the ceramic finish.

Clay Bar: Helps in decontaminating the surface by getting rid of embedded fragments, ensuring a smooth application.

Application Pads or Applicators: Utilized for uniformly spreading out the ceramic spray finish onto the surface area.

Proper Surface Area Prep Work Methods

Efficient surface preparation is basic to guaranteeing the effective application of ceramic spray layer in various markets. To accomplish optimal outcomes with ceramic spray layer, proper surface prep work strategies have to be employed.

The primary step in surface area prep work is complete cleansing. ceramic spray coating. Any kind of dust, wax, oil, or deposit must be entirely eliminated from the surface area to make sure proper bond of the ceramic finishing. This can be done making use of a specialized surface or a mild detergent cleaner

Next, the surface area has to be polished to remove any kind of imperfections such as swirl marks or scrapes. This step not only enhances the appearance of the surface however likewise guarantees a smooth and also application of the ceramic coating.

Application Tips for Optimal Outcomes

To guarantee Visit Your URL exceptional end results with ceramic spray coating, meticulous interest to application strategies is vital following the meticulous surface prep work treatments. When using ceramic spray coating, it is critical to operate in a controlled environment devoid of direct sunshine or strong winds. Optimum application problems usually include modest temperature levels and low moisture degrees to promote proper treating and bonding of the finishing to the surface.

Prior to application, drink the ceramic spray covering container strongly to guarantee the formula is well combined. It is necessary to work in tiny areas to assure detailed application and avoid the layer from drying prematurely.

After applying the ceramic spray finishing, enable sufficient time for it to treat according to the manufacturer's directions. As soon as cured, use a top quality microfiber towel to delicately rub the surface area to a high gloss coating. By adhering to these application suggestions vigilantly, you can achieve ideal outcomes and optimize the protective advantages of ceramic spray covering.

Upkeep and Long Life Methods

Sustaining the longevity and safety qualities of ceramic spray coating calls for methodical and consistent maintenance techniques. To make certain the finishing remains reliable, normal cleaning with a pH-neutral car hair shampoo is important.

Regular examination of the finishing is also important for identifying any locations that may need touch-ups or reapplication. This can be done by doing an easy water beading examination or aesthetically checking the surface for any kind of indications of wear. Resolving any kind of problems immediately can help keep the layer's safety residential properties and prolong its lifespan.

Additionally, avoiding harsh chemicals, rough cleansers, and automatic that site vehicle cleans can help protect the stability of the ceramic spray coating. By complying with these upkeep strategies, professionals can guarantee their ceramic-coated lorries keep a high degree of defense and visual allure for an extended period.

Conclusion

To conclude, achieving specialist results with ceramic spray finish requires mindful consideration of necessary devices and products, appropriate surface prep work strategies, and application ideas for ideal outcomes. By following tested techniques and ideal practices, upkeep and long life of the covering can be made best use of. It is essential to stick to these standards in order to attain the desired expert outcomes and make certain the efficiency of the ceramic spray covering.

As professionals in the field of automobile outlining and surface area defense are constantly looking for methods to boost the top quality of their work, the application of ceramic spray finishings has emerged as a browse this site game-changer.In addition, ceramic spray coverings create a hydrophobic surface that fends off water and protects against water areas, making cleansing and upkeep simpler and less taxing. In verdict, the benefits of ceramic spray covering make it a preferred choice for securing and enhancing surface areas in a range of applications.

To make sure outstanding results with ceramic spray coating, meticulous interest to application strategies is critical following the meticulous surface preparation treatments.In conclusion, accomplishing professional results with ceramic spray finish requires cautious factor to consider of crucial tools and products, proper surface area preparation strategies, and application ideas for optimal results.

Report this page